On issue of the reproductive capacity that reported in local media in which in Selangor and Negri Sembilan for the period 1948 - 1952 about 250 mature females of the ricefield rat and the Malaysian wood rats were examined. The pregnant females made up 14% of the ricefield rat and 12.5% of the Malaysian wood rat. in all quarters of the year, without significant seasonal variation in number. Litter size was 5-8, mean 7 for the ricefield rats, and 4-10, mean 6 for the Malaysian wood rat. Similar to the house rats (Rattus rattus diardii, R. norvegicus, R. exulans) in which the sexual maturity of young ricefield and Malaysian wood rat is reached in about 90 days of age, and the rats are reproductive by the fourth month. Studies by local universities indicated a mean length of life in the wild for R. argentiventer of 6.2 months and for R. tiomanicus of 3.6 months. Pregnant females of Bandicoota indica from Kedah and Perlis (three instances), were found to have litter size of 5 -10. The litter size of B. bengalensis (four instances) from Penang was 7 - 11. B. indica in Vietnam 3 - 8, Thailand 4 - 9. B. bengalensis in Vietnam 2 -12 and Burma 6-11. Males attain sexual maturity at body weight of 284 gram, females at 186 g for B. indica. Pregnant females of Mus caroli have been recorded with litter size 5-6 in Vietnam.

Do you know there are people eating rats as sources of food?.

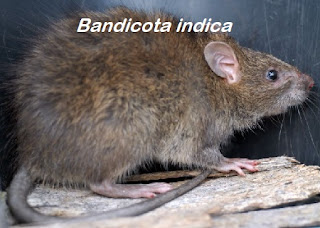

During World War II reported that when meat was not easily available in a large forest and field rats of 250 g and above were trapped for food. Among the field rats are the greater bandicoot rat (Bandicota indica) in the ricefields were the prime choice for consumption by some ethnic groups in Thailand, Vietnam, Cambodia, Myanmar, China and India. In the study conducted by experts in listed country reported that they tasted some properly boiled meat of the forest giant rats including the greater bandicoot rat and found the meat to be bland in contrast with that of domesticated mammals.

Talk about rats related to rodent-borne diseases. Reported that the four species of field rats with the exception of the field mouse, like the house rats, are reservoir hosts of diseases to man; such as waterborne diseases (leptospirosis), bacterial diseases (plague), rickettsia diseases (scrub and murine typhus), helminthic diseases (angiostrongyliasis, echinostomiasis , hymenolepiasis, trichninellosis) and viral diseases (haemorrhagic fever with renal syndrome, rat-bite fever). Among these diseases, leptospirosis is the most prevalent among the field rats. As for the field mouse, information of its public health importance is not available. In Malaysia, the ricefield rat (Rattus argentiventer), greater bandicoot rat (Bandicota indica) and the ricefield mouse (Mus caroli) are habitat-specific and major rice field pests. The latter two species B. indica and M. caroli are confined to the northern parts of Peninsular Malaysia only, thus damage to rice production is restricted. R. argentiventer known is widely distributed through all the states of Malaysia, and the destruction to the productivity of rice is thirteen fold that of the other two species. The Malaysian wood rat (R. tiomanicus) is non habitat-specific, but with preference for oil palm and is a major pest in oil palm estates. This rat and the house rats, like Rattus rattus diardii, R. norvegicus and R. exulans are also intermittent visitors to ricefields. The lesser bandicoot rat (B. bengalensis), on the other hand, is restricted to Penang island. It is an outdoor resident in urban and suburban areas, and has yet been trapped in ricefield plots despite several fauna inventories by IMR in the 60’s and 70’s, and DWNP (Department of Wildfile and National Parks) in the 1990s. During the period 1950-1970, bio-ecological studies on the house and field rodents were conducted in Peninsular Malaysia (then Malaya) by four research organizations. The Institute for Medical Research (IMR) hosted two research units: the Scrub Typhus Unit headed by Professor J.L. Harrison, and the U. S. Army Medical Research Unit headed by Colonel R. Traub of the Walter Reed Medical School, U.S.A. These two units were working on the scrub typhus disease of which house and field rodents are reservoir hosts. In the latter part of this period, Mr. Brian J. Wood of the Sime Darby organization carried out studies on rodent pests in oil palm plantations, while the Agriculture Department in Serdang under Dr. W.P. Ting worked on rodent pests in rice fields, orchards and plantations. These pioneer researchers developed various control methods on rodent pests particularly in oil palm estates, and also paved the way for bio-medical studies on rodent-borne diseases by research scientists in the universities. Since the late 1960s, deforestation has been rampant for the expansion of oil palm. At the same time, large plots of rice and rubber have been converted to oil palm. This has resulted in changes in the behavior of fauna. A good example is the common tree-shrew (Tupaia glis), once confined to forest and forest fringe habitats, now well-adapted to plantations. It has also become a common animal in urban parks and gardens. Similar adaptation by some rodent species (rats, squirrels, small carnivores) and other vertebrate species such as amphibians and reptiles to plantations, particularly oil palm plantations, is to be expected. This article devided in three segments namely Part 1, Part 2 and Part 3 respectively. Thanks...all.